AFRY Fleet

Loading page...

AFRY Fleet is a powerful tool designed to analyze the operation and maintenance (O&M) of fleets comprising multiple systems. A "system" can refer to a vehicle or any other item that experiences failures and requires maintenance actions. The tool constructs a comprehensive fleet model, incorporating system failures, maintenance resources and levels, standby systems, logistics delays, spare parts, queuing priorities, special skills/tools, and other relevant details. The tool features a user-friendly interface tailored to specific needs, making it accessible to users without specialised modeling skills.

The steps included in fleet operation modeling are as follows:

- Define failure modes of each system.

- Specify the Mean Time To Failure (MTTF) or failure distribution of each failure mode.

- Specify the Mean Time to Repair (MTTR) or repair distribution of each failure mode.

- Define the schedule of preventive maintenance actions.

- Define domain-specific details, such as standby systems or special usage/operation profiles.

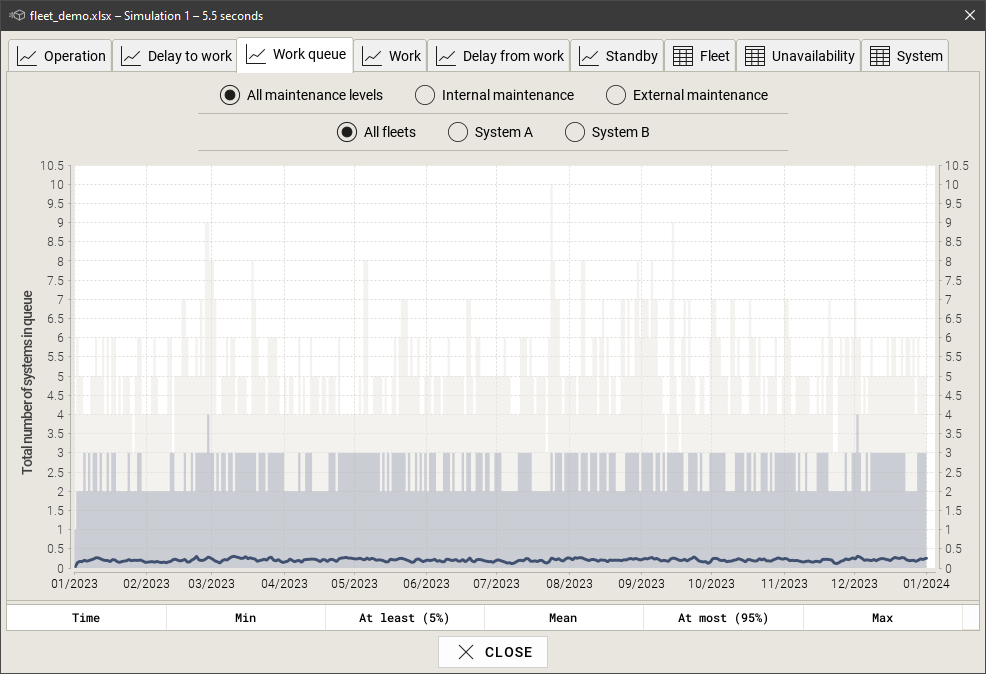

The steps included in maintenance organization modeling are as follows:

- Define the number of available maintenance personnel, workshops, and other resources.

- Specify logistics delays for transportation to and from maintenance activities.

- Determine the required spare parts.

- Establish priorities for maintenance operations if queueing is necessary.

- Define domain-specific details, such as separate levels of maintenance organization or critical tools/resources.

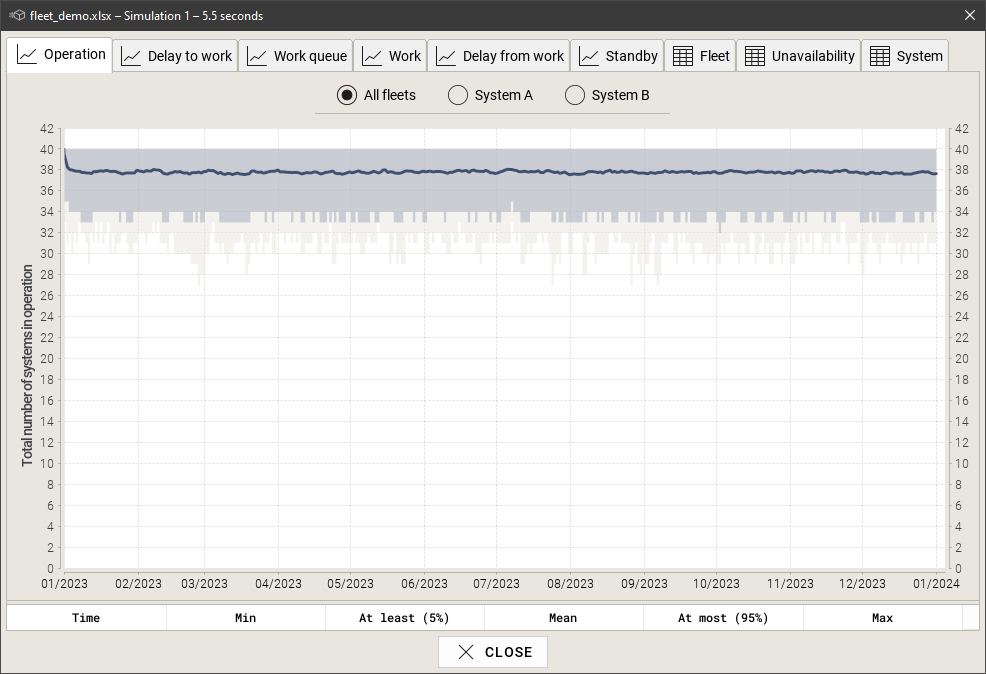

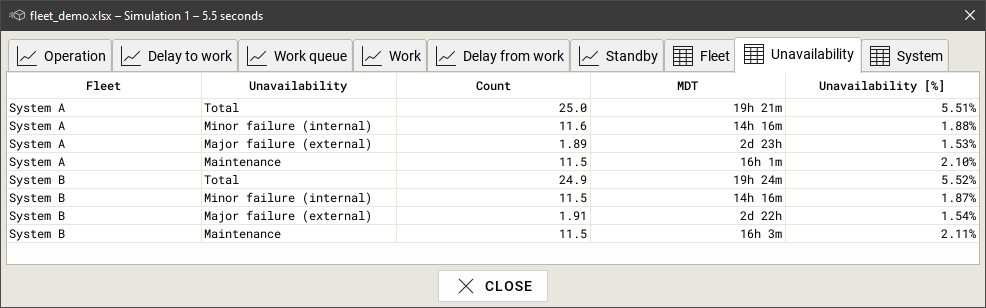

Fleet availability simulation provides answers to questions such as:

- What is the average number of available systems with the current maintenance organization?

- How would changes in maintenance organization or actions affect fleet availability?

- How well could the maintenance organization adapt to changes in usage profiles or an increased number of systems in the fleet?

AFRY Fleet – Licenses

We tailor AFRY Fleet to meet your specific needs. Our flexible software provides a user-friendly interface for complex interdependencies between maintenance organizations and system fleet operations. We have a demo version available with essential features to demonstrate the capabilities of our software. If you are interested, we can provide you with the demo version for evaluation and initiate discussions on customizing the user interface, analysis features, and tool license to align perfectly with your specific requirements. Simply contact us by email at reliability@afry.com.

Contact

If you require technical support or have any inquiries about AFRY Reliability Tools, please feel free to contact us via email at reliability@afry.com. For information about AFRY's solutions and services related to AFRY Fleet, we invite you to visit AFRY Reliability Management section or AFRY RAMS services web pages.

Unlocking transitions

At AFRY, we unlock transitions towards a sustainable and resilient society. While others are talking about the future, we are making it. Through our deep-sector expertise, we help our clients where need for transformation is evident. Together, we turn challenges into opportunities and shape progress that lasts.

We provide engineering, project management, and advisory services that enable the energy and industrial transition and strengthen resilience in society. With 18,000 experts worldwide, we combine a global reach with local insights and deep sector knowledge to make a lasting impact for generations to come. Find out more: https://afry.com

Transforming challenges into action – we unlock transitions.

File downloads: AFRY Fleet

To access AFRY Fleet file downloads, please log in using your AFRY Reliability Tools user account.

Log in to the AFRY Reliability Tools portal for file downloads

If you don't have an AFRY Reliability Tools user account yet, please reach out to us by email at reliability@afry.com.